Batter: Once the oils and lye used to make soap are combined – emulsified – this liquid state is commonly referred to as “soap batter”. The longer you blend the soap batter – or leave it for the chemical reaction to take place – the thicker the batter becomes – known as “trace”.

Trace: At thin trace, there will be no streaks of oil and the soap will be the consistency of thin cake batter. As the soap sits, it will continue to thicken to medium trace (heavy cream) and thick trace. Thin trace is ideal for creating blended colours or fine swirled lines; medium trace works well for “in the pot” swirls or “hanger” swirls, and thick trace is perfect for layered or textured soaps.

Gel phase: During the initial saponification phase, soap can get as hot as 80°C and can develop a gelatinous look. This “gel phase” doesn’t occur all of the time and it is important to know under what conditions it can occur, as there may be times when you want your soap to gel – it enhances colours and gives the soap a slight shine – or other times when you may not want this to happen – if you want a matt look or muted colours. Gel phase is more likely to happen when you make soap at slightly higher temperatures, or in warmer rooms, or if you insulate or heat your soap. Some makers force their soap through gel phase with blankets and heating pads. Gel phase only affects the look of the bars, not the performance or quality. If you want to avoid gel phase, you can freeze your soap for the first 24 hours after the pour – if you want to force it, you can insulate with blankets or a heating pad.

Curing: Whilst cold process soap is usually safe to use after a few days – once the saponification process is completed – it is recommended that soap is left in a cool, dry place with good airflow for between four and six weeks. This allows excess water to evaporate and creates harder, longer lasting bars of soap.

Lye Calculator: In order to ensure your soap is safe to use, it is vitally important that you correctly calculate the amount of lye to use with your oils. The amount of lye to use depends on not only the amount of oil in the recipe, but also the types of oils, as some oils require more lye to saponify completely than others. Too little lye and you will just have an oily, sticky, unpleasant result. Too much lye, and the soap ends up dry, hard and brittle and can irritate the skin (see below). Using a recipe calculator such as can be found here takes the guess work out of the process. All you have to do is enter the oils in your recipe by weight or percentage and the Lye Calculator will give you the lye and liquid amount you need for your recipe. It also calculates the superfat level.

Superfat: When making soap, the intent is to introduce lye to oil to create a chemical reaction to turn the oil into soap. If the lye to oil ratio is exact, then every last bit of oil will be combined and turned into soap, and would leave nothing behind to nourish or moisturise the skin. Superfat is therefore the amount of oil left over after the lye has been exhausted by combining with the oil. I make a soap for my husband with 0% superfat as he prefers not to have any moisturising benefits from the soap – and for a baby soap or a men’s shaving soap, I will have 6 or 7% superfat for the additional moisturising properties.

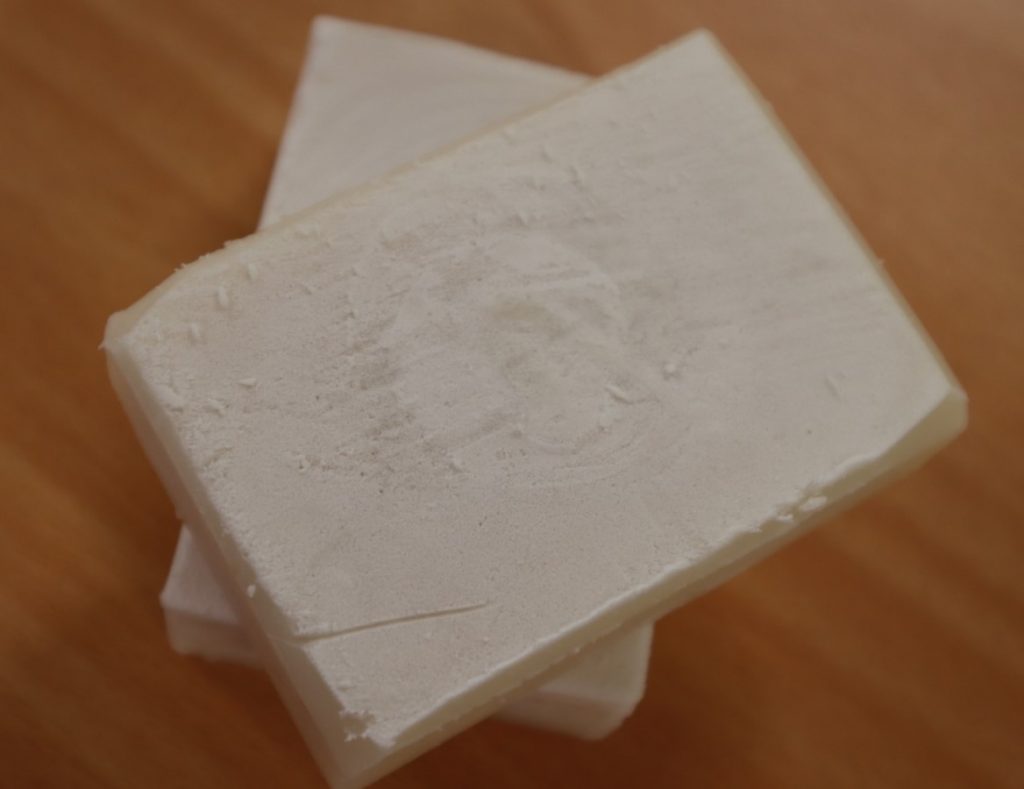

Soda ash: This is an uneven, white, ashy film that can appear on soap, particularly those made with dark colourants such as activated charcoal or dark micas, although it can occur on pretty much any bar as it is formed when saponified lye reacts with naturally-occurring carbon dioxide in the air.

The soap is still safe to use and is not affected in terms of quality at all, however it can make the soap less visually appealing. It can be prevented or minimised by using a slight water discount, forcing gel phase, or spritzing with isopropyl alcohol once poured. You can also steam your soap once it has cured or – even simpler – simply run it under water for a few seconds and then leave to dry, as was done with the example bars below.